High frequency welding D type pipe

Material Thickness:0.8-3.0mm

Composite layer/Alloy material:4045 & 4343/3003

Key words:

High frequency welding D type pipe

Sunshine Aluminum

Classification:

High frequency welding pipe

E-mail:

- Product Description

- Advantages & Applications

- Company

-

Aluminum High Frequency Welded Tube is also called Aluminium HFW Pipe. It is manufactured by forming a flat strip of aluminum into a tubular shape and then joining the edges by a high-frequency welding process, and seam welded without the use of any filler material. The welded tube is then adjusted in size until reaching the exact size and tolerances.

The aluminum high frequency welded tube is a kind of composite tube. The main difference between extruded and drawn tubes is the possibility to have a weldable layer material of different aluminum alloys. Generally, the core material is 3003 and the clad weldable alloy is 4343 or 4045. It is widely used in tubes for heat exchanger production to enable the furnace or flame to braze and to give sacrificial corrosion resistance.

In addition to the welded tube with a weldable alloy, we also supply another kind of aluminum composite tube, which is an al-al composite drawn seamless tube with multi-layer material, mainly used as a condenser header pipe.

Our aluminum high frequency welded tubes are manufactured with high precision and extremely low tolerance to meet the customer’s specific requirements, and welded tubes can be created in a variety of different sizes and shapes from a wide range of alloys. The most common shapes are round, flat, oval, rectangular, and square, thin-walled or thick-walled aluminum tubes are also available. The general standard inventory sizes and customized specifications are available for inquiry.

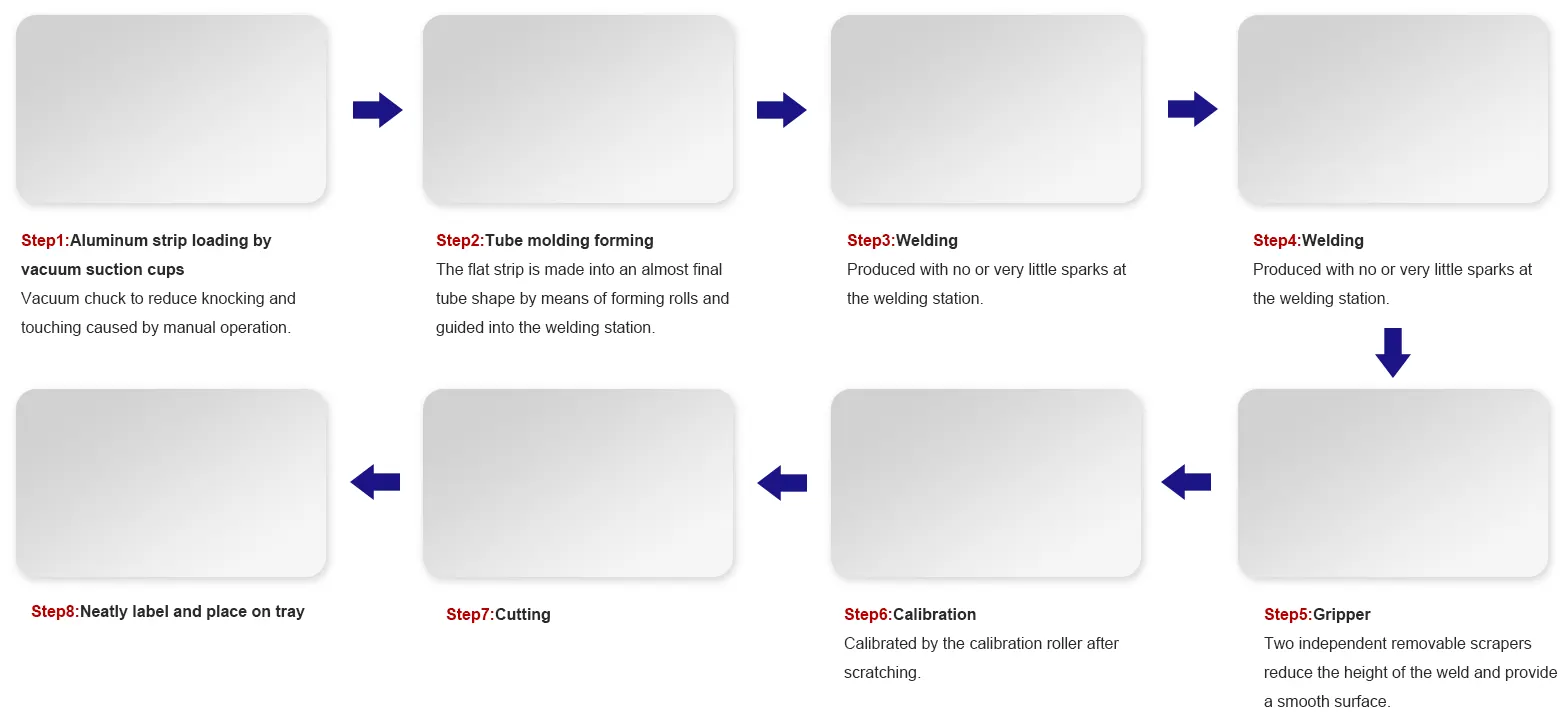

Production process

Options of Aluminum High Frequency Welded Tube

1.Aluminum high frequency welded tube for radiators (high frequency welded radiator tube).

2.Tubes with inserted turbulators (high-frequency welded intercooler tube).

3.Round tubes for condenser header (parallel-flow condenser high-frequency header pipe).

4.Aluminum folded multi-channel tube.

5.Battery case for new energy automotive.

-

Applications of Aluminium High Frequency Welded Tubes

The aluminum high frequency welded tubes are ideal for heat transfer applications where weight and space are design concerns, including in HVAC units, automotive heat exchange systems, manifolds, evaporators, and condensers. It can also be applied in electrical conduits and general tubing for plumbing and construction

Automotive Applications of Aluminium High Frequency Welded Tube

● Flat oval aluminum welded tubes for radiators.

● Round aluminum welded tube for condenser headers.

● Rectangular welded tubes for charge air coolers (CAC tubes).

● Thick-walled rectangular aluminum welded tube for oil coolers.

● Internal enhancements such as dimples or turbulators increase heat transfer.

● Headers/manifolds for mobile A/C condensers and battery coolers.

● Small-diameter welded aluminum tubes for connector lines.

HVAC/R Applications

● Used as aluminum headers/manifolds for stationary condensers

● Inner-groove welded tubes with high heat transfer performance

● Mechanically expanded heat exchangers

Industrial Applications

● For industrial applications, where strength and formability are important factors, high-strength materials available for high-pressure applications, such as 5xxx-series alloys with the advantages of high strength and good dimensional stability can be utilized.

● Electrical conduits.

● Ladders and scaffolding.

● Special aluminum welded tubes for orthopedical equipment, sports adventure equipment, garden, and forestry.

● Welded tubes with high resistance to corrosion for the desalination industry.

-

Enterprise strength

The company covers an area of more than 150 mu, construction area of 65000 square meters. It has 206 employees, including 120 with college education or above, 10 technical engineers, 2 registered safety engineers, 5 accountants, 3 human resources managers and ISO9000/SO14000. There are 5 sms18000 internal auditors who have passed the ISO9001:2008 and ISO/TS16949 quality system certification.

The company has a number of horizontal extrusion production lines, LLJ300B aluminum continuous extrusion production lines, and South Korea imported CNC flat tube straightening and cutting production lines. At the same time, it also introduces the world's advanced professional arc spraying equipment and technology, which not only improves the traditional aluminum flat tube Comprehensive performance, and makes the corrosion resistance of the zinc spray flat tube particularly prominent. Once the product is used, it is well received by customers.

Since its establishment, our company has strictly followed the service policy of honesty and sincerity, and won the lasting trust of customers; the company adheres to the business principles of advocating perfection and striving for perfection, and "creating value with science and technology" as the essence, and is committed to becoming a pioneer in the production of zinc-sprayed aluminum flat tubes for green environmental protection automobile air conditioners in China!

Production Equipment

Leave A Message

SAF Coolest v1.3.1.2 设置面板 RZQSX-AYZG-YSZQE-AAD

无数据提示

Sorry, the current section is being updated, stay tuned!

You can view other columns or return to the home page