Parallel flow micro-pore necking nozzle zinc-aluminum flat tube

High:1.0-8.0mm

Number of holes:5-45

Meter weight:0.02-0.15kg

The spraying process is:Zinc-coated Aluminum Tube, Pre-Flux Coated Aluminium Tube, Si Flux Coated Aluminum Tube

Key words:

Parallel flow micro-pore necking nozzle zinc-aluminum flat tube

Sunshine Aluminum

Classification:

(MPE)Micro-channel spray zinc aluminum flat tube

E-mail:

- Product Description

- Advantages & Applications

- Company

-

Aluminium Multi-channel Tube Description

Aluminum multi-channel tube is also called aluminum multi-port tube. It’s for the auto air-conditioning industry.

Aluminum multi-channel tube contains a common aluminum pipe, sharp corner pipe, internal tooth pipe, zinc spraying pipe, conjoined pipe, intercooler flat pipe and other special pipes. mainly be used on the automotive air conditioner, public air conditioners, heat exchangers, condensers, evaporators,Battery heat dissipation, etc.

The big or small multi-channel tubes are available in various sizes and alloys, ensuring the best properties for the purpose required.

Tolerance of Aluminum Micro-channel Tube

Item Range Fixed length 120mm-6000mm Width (aluminum micro-channel tubes) 8mm-150mm Thickness 1mm-8mm Number of holes (hole) 5-45 Wall thickness 0.15mm-0.6mm Thickness of zinc spraying 5g/㎡-15g/㎡ Thickness of flux coating 8g/㎡-25g/㎡ Tolerance of Aluminum Micro-channel Tube

Width Thickness Wall Thicknesses Length Straightness (side) Straightness (front) Twisty ±0. 04mm ±0. 03mm ±0. 05mm ±0. 30mm ≤L*0.15% ≤L*0.15% ≤L*0.10% Chemical Components of Aluminum Micro Channel Tube

Grades Temper Si Mg Cu Fe Ti Mn Zn Other 1100 H112 <0.15 <0.05 0.1-0.15 0.15-0.20 0.015-0.025 <0.05 <0.05 <0.05 3F03 H112 0.05-0.10 <0.03 0.05-0.10 0.10-0.15 0.01-0.02 1.03-1.1 <0.05 <0.03 3102 H112 0.05-0.10 <0.03 <0.03 0.12-0.18 0.015-0.025 0.25-0.33 <0.05 <0.03 D1197 H112 <0.15 <0.05 0.4-.05 <0.15 <0.05 0.1-0.2 <0.05 <0.05 3003 H112 <0.6 <0.03 0.05-.020 <0.7 <0.05 1.0-1.5 <0.05 <0.05 HG103S H112 ≤0.20 ≤0.05 0.4-0.5 ≤0.20 <0.05 0.1-0.3 ≤0.05 ≤0.05 9153 H112 ≤0.30 ≤0.05 ≤0.05 ≤0.20 ≤0.05 0.70-1.20 ≤0.05 ≤0.05 3103 H112 0.10 0.05 0.01 0.12 0.05 0.9-1.10 <0.05 0.03 Coating Standard and Corrosion Resistance of Aluminum Micro Channel Tube

Corrosion resistance (common alloy) Salt spray test: ≥720 hours Zn Coating standard 5.5+2.5g/㎡ 7+2g/㎡ 10+2g/㎡ 12+2g/㎡ Flux Coating standard 4.5±1.5g/㎡ 10+2g/㎡ 15±2g/㎡ 3 Kinds of Coating Solutions for Aluminum Micro-channel Tube

Coating Material Pre flux coating Si Braze coating Zinc spray layer SampleImages

Main Components Flux(K1-3A1F46) NOCLOK F1ux: 66.6% Silicon Powder: 33.3% or customized according to customer requirements Zinc powder

FeaturesNo need to spray flux during brazing, which improves efficiency and is more environmentally friendly. No additional brazing agent is required in the brazing line, it can be directly welded to the accessory, and the fins can be made of non composite materials. Zinc spray flat tube can greatly improve the corrosion resistance Production Line and capacity

SHANDONG SUNSHINE ALUMINUM is one of the biggest aluminum micro-channel tube supplipers in China,comprehensive annual capacity can reach 13000T

Main Production Line Qty Products Annual Capacity Extrusion Line 12 MPE Tube in Coil 13000T Cutting Line 14 Fixed Straight Length 10000T Tooling R&D Manufacturing Center 1 Extrusion Die 8000PCS Zinc Coating 12 Zinc Coated Tube 13000T Si-Flux Coating 2 Si-Flux Coated Tube 2000T Production Process

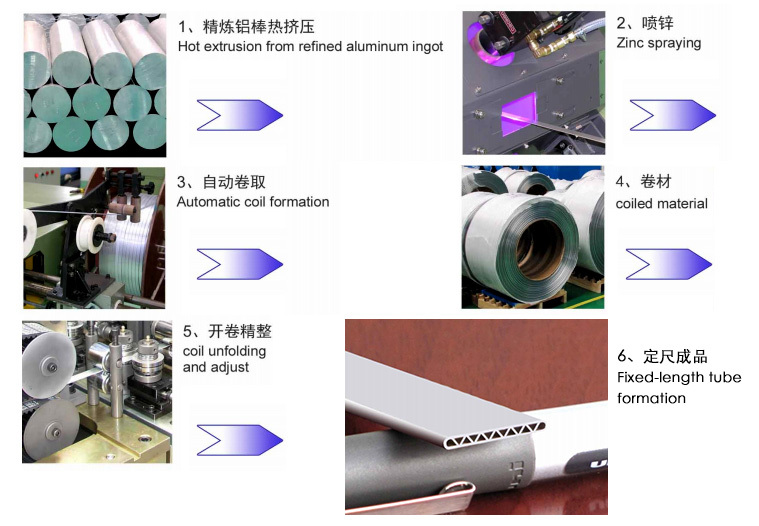

The manufacturing processes consist of heat molds and aluminum billet, extrusion, zinc spraying, cooling(flux coating), rolling and cutting.

Alloy

1100,1197,1070,3102,3103G,3F03,3003,9153A...

Standard

ASTM /GM

Characteristics of Aluminum Multi-channel Tube

● Lightweight

● Corrosion-resistant

● Excellent heat transfer performance

● Tighter tolerances

● Reduced assembly time

● High level of surface quality

● Big and wide aluminum extrusions for diverse applications

Packing Detail of Aluminum Multi-channel Tube

1. Our products are packed and labeled according to the regulations and customer requests.

2. Great care is taken to avoid any damage which might be caused during storage or transportation.

3. The standard export packaging, plastic film or craft paper covered.

4. Wooden case or wooden pallet is adopted to protect products from damage during delivery.

5. Also, clear labels are tagged on the outside of the packages for easy identification of the products and quality information.

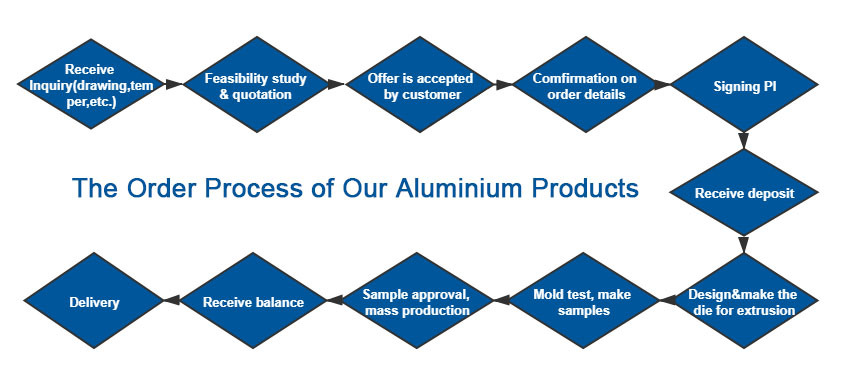

Order Process of Aluminum Multi-channel Tube

-

Enterprise strength

The company covers an area of more than 150 mu, construction area of 65000 square meters. It has 206 employees, including 120 with college education or above, 10 technical engineers, 2 registered safety engineers, 5 accountants, 3 human resources managers and ISO9000/SO14000. There are 5 sms18000 internal auditors who have passed the ISO9001:2008 and ISO/TS16949 quality system certification.

The company has a number of horizontal extrusion production lines, LLJ300B aluminum continuous extrusion production lines, and South Korea imported CNC flat tube straightening and cutting production lines. At the same time, it also introduces the world's advanced professional arc spraying equipment and technology, which not only improves the traditional aluminum flat tube Comprehensive performance, and makes the corrosion resistance of the zinc spray flat tube particularly prominent. Once the product is used, it is well received by customers.

Since its establishment, our company has strictly followed the service policy of honesty and sincerity, and won the lasting trust of customers; the company adheres to the business principles of advocating perfection and striving for perfection, and "creating value with science and technology" as the essence, and is committed to becoming a pioneer in the production of zinc-sprayed aluminum flat tubes for green environmental protection automobile air conditioners in China!

Production Equipment

Leave A Message

SAF Coolest v1.3.1.2 设置面板 RZQSX-AYZG-YSZQE-AAD

无数据提示

Sorry, the current section is being updated, stay tuned!

You can view other columns or return to the home page